BARRELS

BERGARA MAKES PRECISION BARRELS FOR PRECISION RIFLES

Bergara has quickly become one of the most respected barrel makers in the world. Our barrels are manufactured in Bergara, Spain, and being used by numerous top-tier gun manufacturers in both Europe and the United States.

A HISTORY OF PRECISION

Manufactured in Bergara, Spain, a region known to produce some of the finest guns in the world, Bergara has combined the most technically-advanced barrel manufacturing equipment with an unwavering commitment to quality and value. This superior technology combined with decades of barrel making experience delivers a production barrel that performs like it was custom made.

Our barrels are used by both, gunsmiths and most advanced gun manufacturers in the world.

We standardized the product portfolio in order to deliver barrel blanks to any gun makes within few days. Additionally, we included the B14 HMR and BMP barrels contours for the shooters who want to switch the barrel to their B14 rifle.

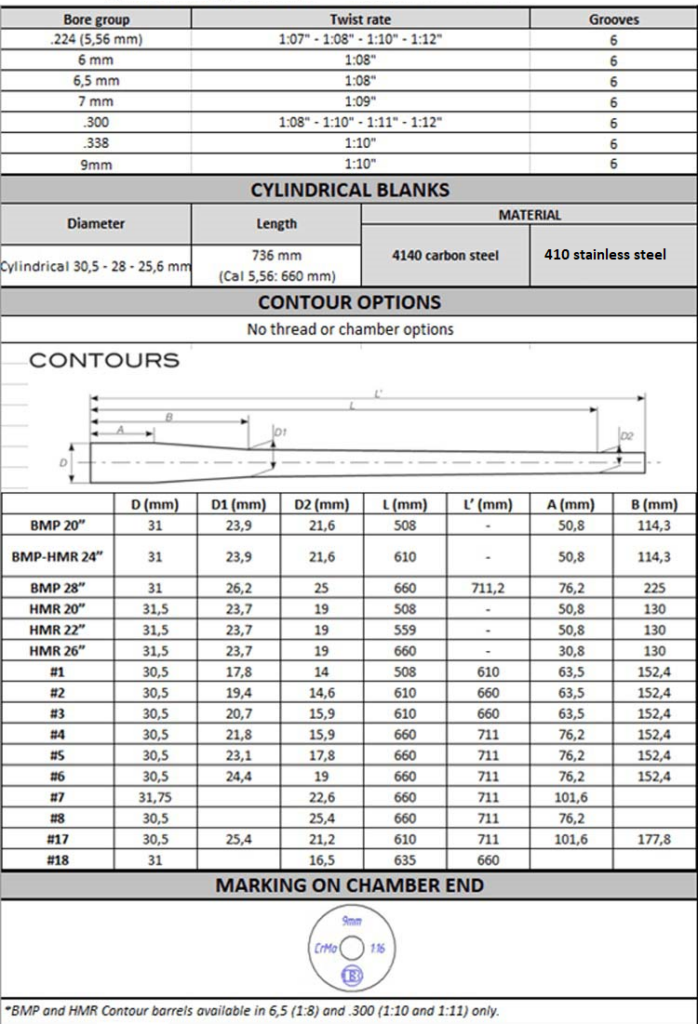

DIMENSIONS

In case you represent a gun factory and you need OEM barrels please send us your drawing to [email protected]

The steps we follow to produce our barrels are:

STEPS

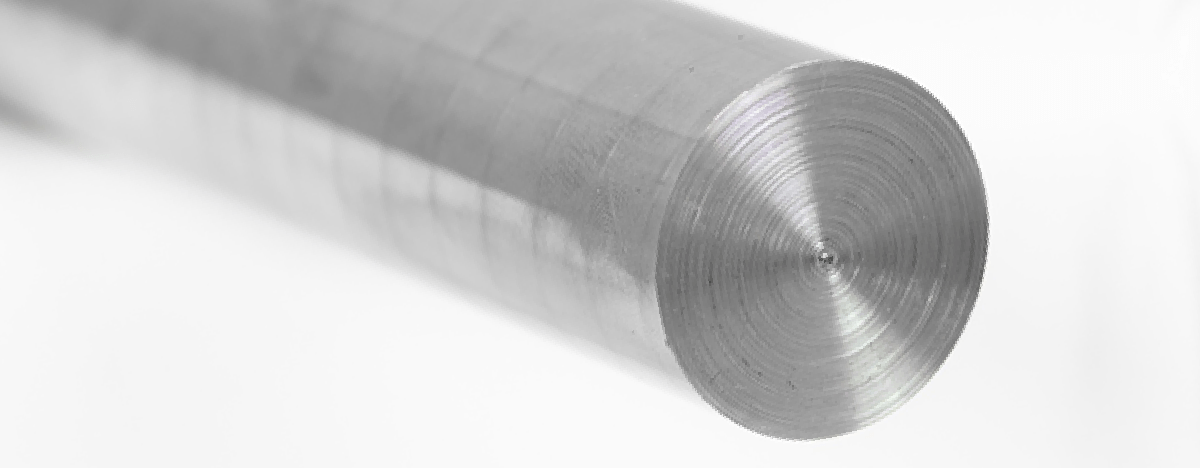

Step Face Turning

The solid bar is face turned in order to assure straight deep hole drilling.

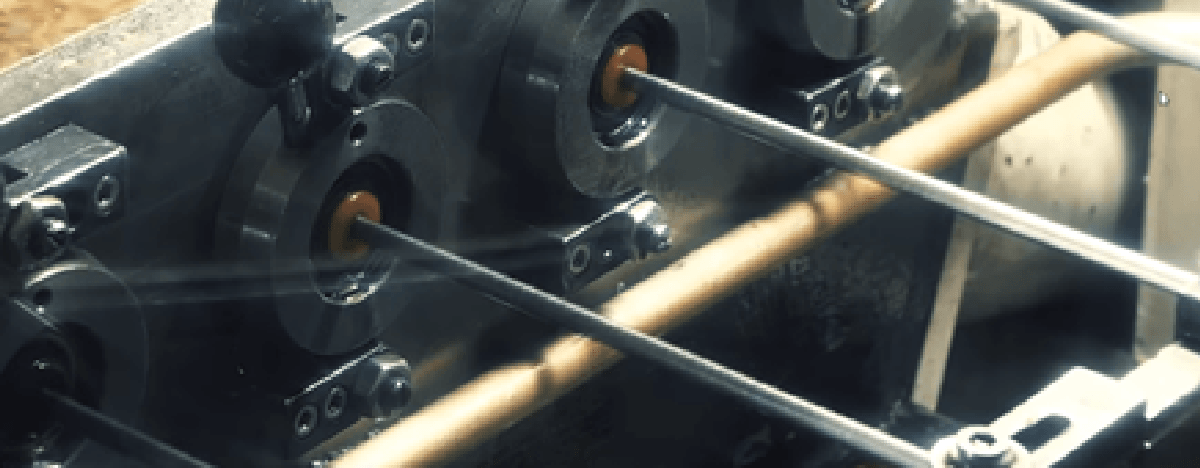

Step Deep Hole Drilling

Once the steel bar is straightened, it moves on to a four-spindle deep hole drilling machine where a specialized bit drills a perfect hole through the entire length of the bar.

Step Turning

Turning the barrel before honing helps get a better bore finish.

Step Honing

Most other barrel manufacturers move from deep hole drilling to reaming, a process that leaves tool marks in the bore. Instead of reaming, Bergara uses three separate honing spindles that utilize diamond tipped bits that polish the interior surface of the barrel to a mirror-like finish that is almost completely free of tool marks. This time-consuming step lends Bergara a level of accuracy on par with barrels costing much more.

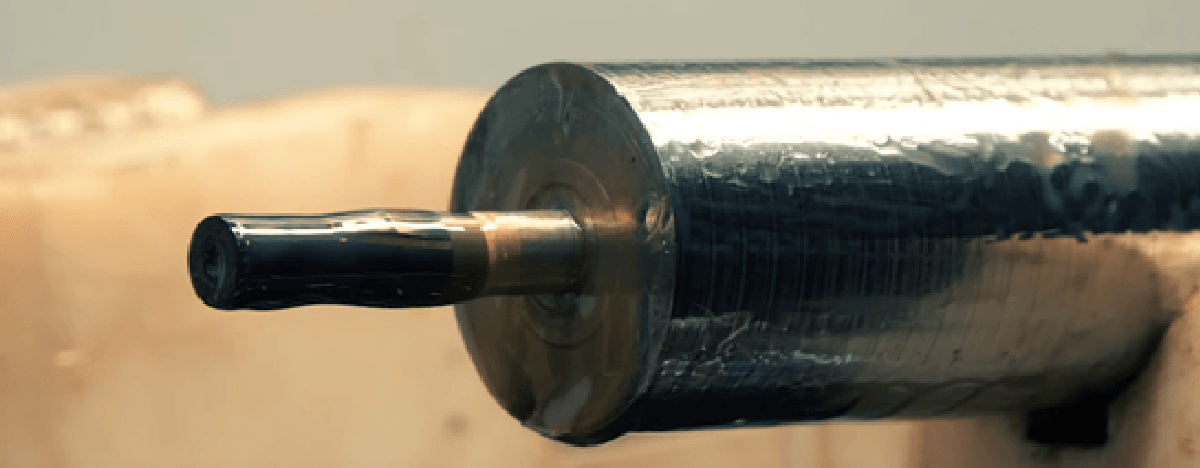

Step Button Rifling

A carbide rifling button is drawn through the barrel to produce the rifling grooves at the appropriate twist rate for each caliber. This produces a groove diameter deviation of less than 2/10,000 (or .0002”) of an inch. It’s the same result that many gunsmiths accomplish by hand lapping.

Step Stress relieving

Finally, a high temperature heating process realigns the steel molecules ensuring that the barrel is free from any stress after the button rifling process. Doing so the barrel will be more reliable and will last more rounds.

Contact

If you need any additional information you can contact us using this form. We will try to answer you as soon as possible.

+34 943 76 98 93

+34 943 76 98 93